QIS Quality Inspection Services

DUPRO & In-Line Inspections for Production Quality Control-QIS

DUPRO & In-Line Inspections for Production Quality Control-QIS

無法載入取貨服務供應情況

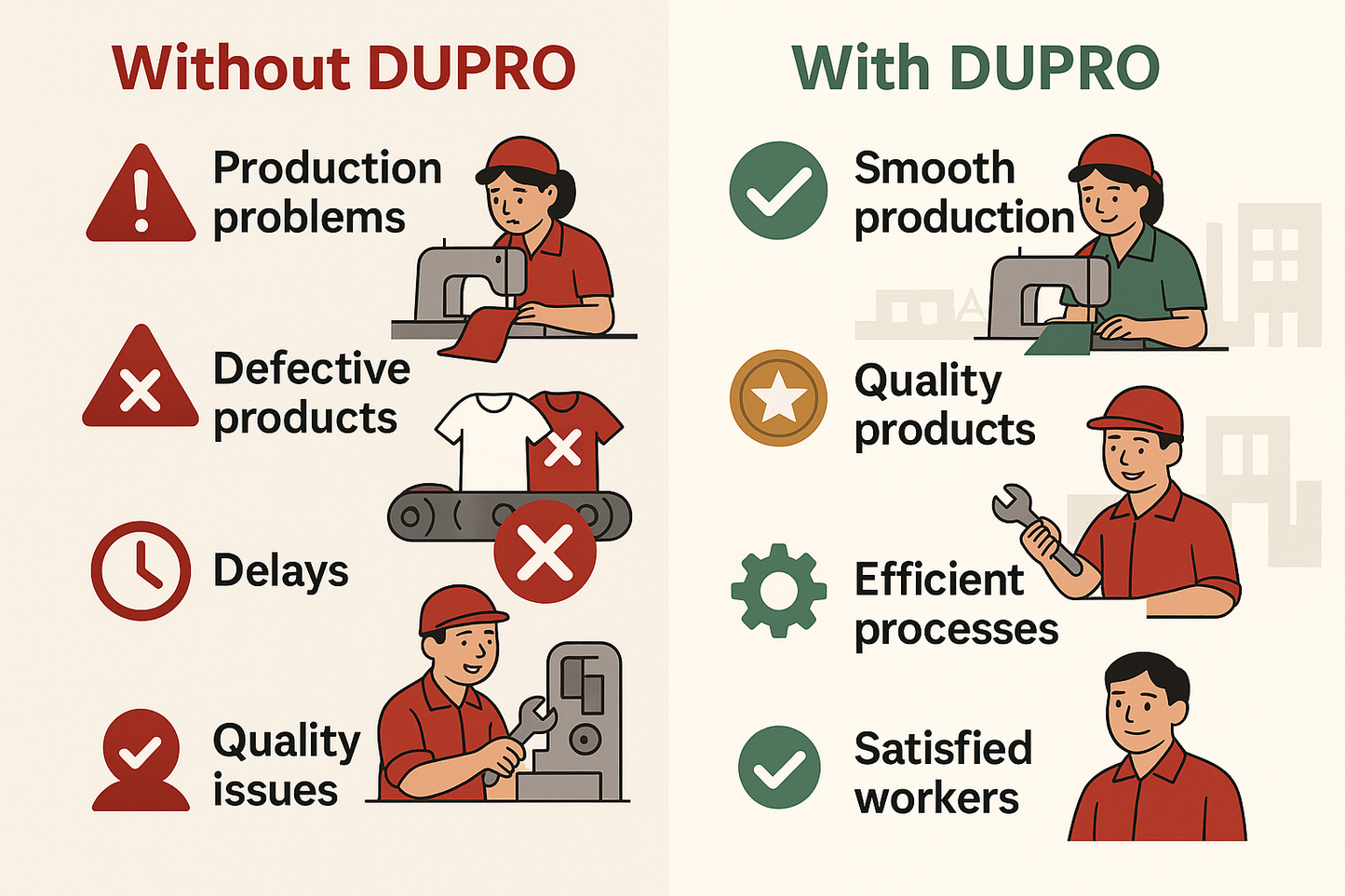

Ensure a seamless production cycle by addressing challenges promptly

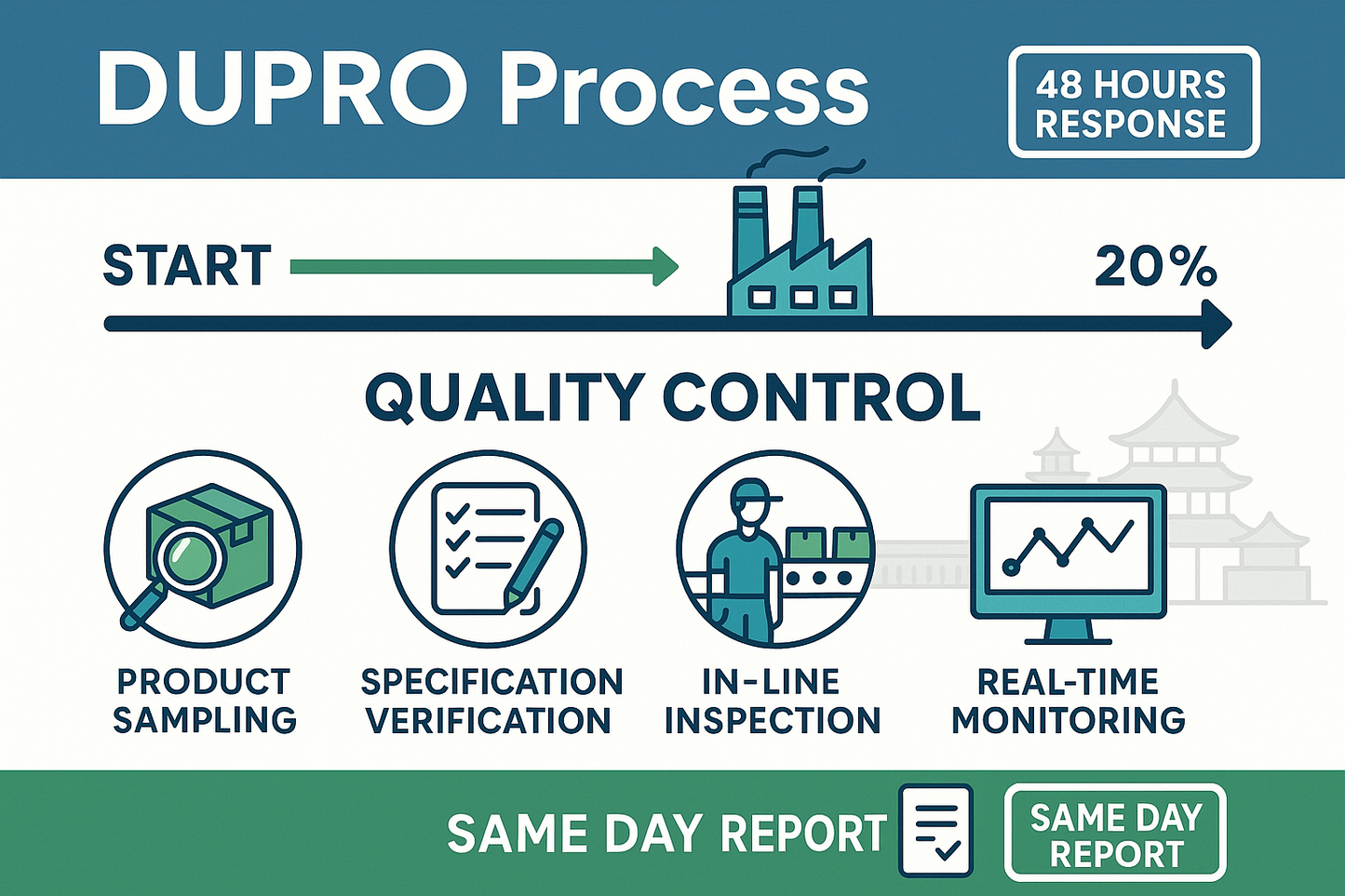

QIS's During Production Check is a comprehensive on-site inspection conducted once 20% of your order has been produced. This service verifies quantities, specifications, and product packaging before the manufacturing process is finalized, helping you prevent delays and resolve ongoing issues.

What is a During Production Inspection - DUPRO?

An IPC is an on-site product inspection performed from before your production begins up until 20% has been completed. In an IPC inspection, inspectors check the quality of raw materials and the first items produced in a production run. These checks are used to identify quality issues early on in production and to prevent them from causing bigger issues further down the road.

Why Perform a DUPRO Inspection?

- Mitigate costly mistakes by identifying issues before a production run is completed

- Implement timely solutions for defective products

- Adjust the manufacturing process to prevent ongoing issues

- Identify potential delays in product delivery

- Verify that your specifications are being followed

- Minimize costly corrections

- Use in-line inspections to address issues in real-time during production

What Checks are Carried Out?

The QIS inspector will first randomly select a sample of products for inspection, following the ANSI/ASQ Z1.4-2008 sampling standard. After the sample has been selected, the inspections are tailored to fit client needs and specific products. We provide a variety of pre-designed inspection checklists suitable for different products, which you can use "as-is." You also have the option to modify these checklists by adding particular checks, or you can develop a completely new checklist that caters to your specific requirements. You can also benefit from our in-line inspections, designed to continuously monitor and address quality issues throughout the production process.

What Happens after a DUPRO is Completed?

Once a during production inspection is completed, a detailed report is provided on our platform the same day. You'll be able to access the report through your online QIMA account. The report outlines the inspection findings, includes photos of any defects, and provides an overall pass/fail assessment. If an in-line inspection was conducted, the results will be integrated into the report.

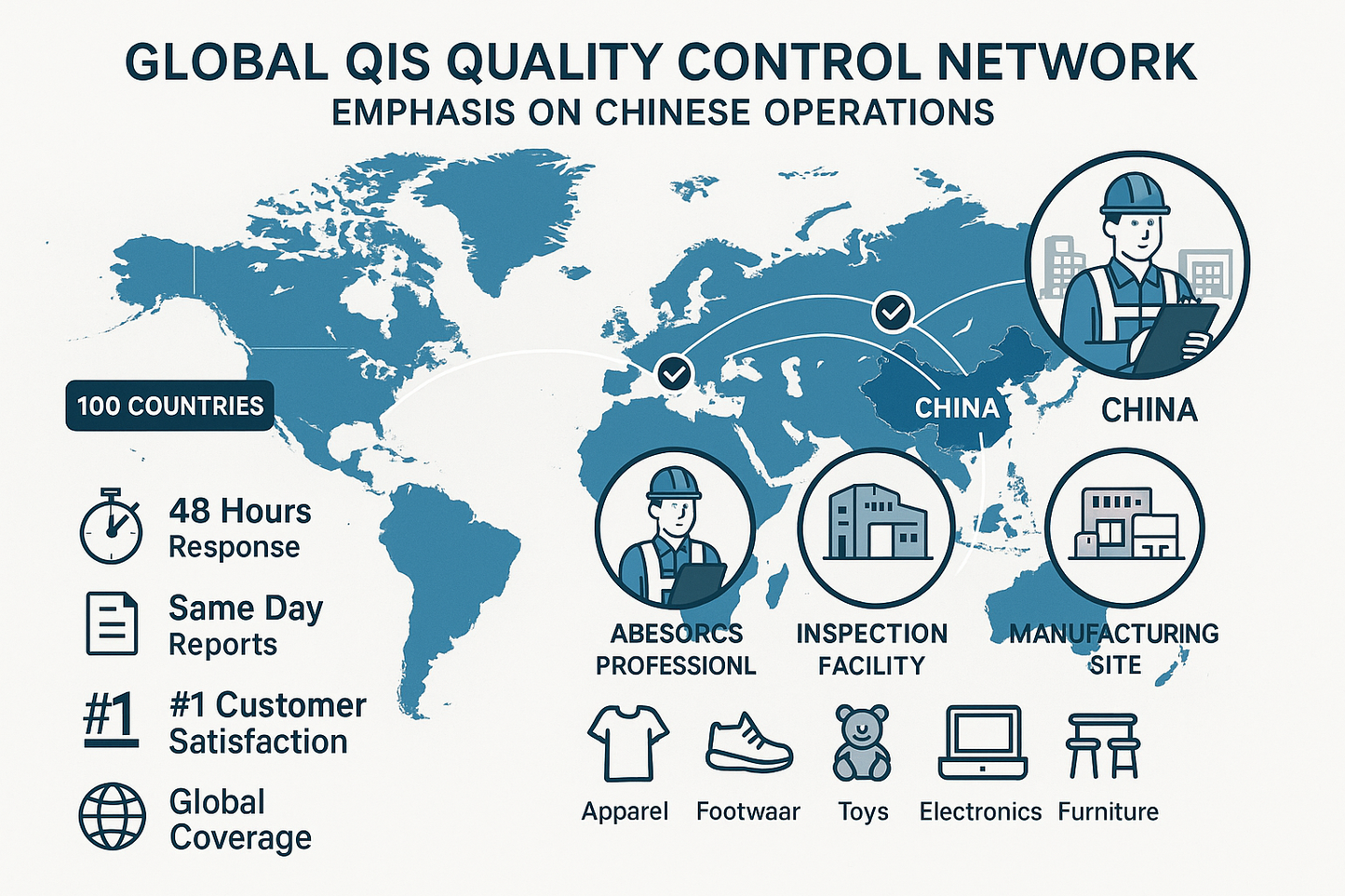

QIS Expertise

QIS provides independent quality control designed to protect your business interests. Our highly trained and experienced inspectors are product experts who undergo regular training in their field of specialization. They can be onsite at your factory within 48 hours of booking, and reports are provided on the same day as the inspection. Our inspections cover a full range of consumer products, including but not limited to apparel, footwear, toys, electronics, and furniture.

QIS Benefits

- Independent quality control performed by product experts to protect your business interests

- Global coverage across 100 countries in Asia, Africa, Europe, North and South America

- Speed and flexibility with an inspector onsite within 48 hours; modify or cancel up to the day before inspection

- Same-day inspection reports tailored for your product

- Online program management to book inspections, make payments, and download detailed reports

- Custom quality dashboard to identify trends and make informed decisions in real time

- Ranked #1 in the industry for customer satisfaction based on independent NPS measurement

Share