QIS

Ethical Audits for a Socially Responsible Supply Chain

Ethical Audits for a Socially Responsible Supply Chain

無法載入取貨服務供應情況

Ensure that the companies and factories in your supply chain adhere to ethical standards

QIS's ethical audit is a comprehensive on-site inspection conducted in accordance with international standards, including SMETA, BSCI, FSLM, WRAP, and other relevant guidelines. This audit helps you identify potential risks, such as labor violations, environmental damage, or unethical practices, so you can address them before they escalate.

What is an Ethical Audit?

An ethical audit, also known as a social compliance audit, is an auditing procedure that allows brands to ensure that their suppliers treat their workers fairly. For your business, demonstrating that products are sourced from ethical supply chains is no longer an optional step, it is a necessity. Consumers, governments, and NGOs are pressuring brands and retailers to comprehensively eliminate unethical practices in their supply chains.

Ethical issues, such as unsafe working conditions, forced labor, or excessive working hours, must be addressed at every level, and a high level of transparency should be demonstrated. QIS ethical audits help companies ensure ethical practices across their supply chains. Our social compliance audits provide both peace of mind and visible proof to consumers and stakeholders that their supply chains are ethically managed.

Why Do You Need an Ethical Audit?

Maintaining ethical standards throughout the supply chain is crucial for businesses that value social responsibility. There are several reasons to use our ethical audit services:

- Ensure that your company and suppliers comply with international labor laws, environmental regulations, and industry standards while reducing the risk of legal issues or fines

- Demonstrate a commitment to social responsibility and enhance the company's reputation

- Identify potential issues such as unsafe working conditions, child labor, discrimination, or environmental harm and avoid negative publicity or legal repercussions

- Strengthen trust with customers, investors, and other stakeholders

- Ensure long-term sustainability of your business

- Enhance employee satisfaction and retention

- Improve your company's Corporate Social Responsibility (CSR) and Environmental Social Governance (ESG) ratings

What Standards Do We Follow?

QIS can conduct ethical audits according to the following international standards:

- Sedex Members Ethical Trade Audit (SMETA)

- amfori Business Social Compliance Initiative (BSCI)

- International Labour Organisation (ILO) Ethical Trading Initiative (ETO)

- Responsible Jewelry Council (RJC) accredited audit

- Initiative for Compliance and Sustainability (ICS) audit

- Ethical Toy Program (ICTI)

- Higg Facility and Social Labor Module (FSLM)

- WRAP (Worldwide Responsible Accredited Production)

QIS's Best-in-Class Ethical Audit Process

QIS auditors will visit a factory and use GPS coordinates to confirm that your products are only being manufactured at the approved facility and no unauthorized subcontracting is taking place. Our Best-in-Class on-site auditing process includes the following stages:

- Opening meeting: Our auditors meet the managers at your supplier's facility for an opening discussion. Audits can be scheduled in advance or conducted without prior notice.

- Factory tour: Auditors thoroughly inspect the facility, including the production area or factory floor, warehouse, canteen, and dormitory, among others. During this tour, auditors assess critical aspects, such as working conditions and health and safety management.

- Documentation review: Auditors go through employment records and other important documents to identify potential issues, such as payment amounts and conditions, working hours, discrimination, or the withholding of employee property, documents, or salaries.

- Employee interviews: Auditors privately interview employees to gain personal insight into conditions at your supplier's facility. Questions may cover a range of potential issues, including but not limited to hiring and firing policies, working hours, working conditions, pay arrangements, the use of child labor or forced labor, and health and safety management. These interviews are voluntary and conducted in complete privacy.

- Closing meeting: Auditors conclude their visit by meeting with the facility's management team to review their findings. If necessary, they will discuss non-compliance issues, suggest steps for improvement, and introduce a corrective action plan (CAP).

Furthermore, our Supplier Workshops (held before and during the audit) help educate your suppliers about the audit program, engage them more effectively, and assist them in achieving compliance. Our worker interviews are structured to ensure transparency and honesty. During the interview, our auditors use voice stress analysis and cross-check information to detect any deception or inconsistencies. Factory staff are also given an opportunity to provide anonymous feedback.

What Happens After an Ethical Audit is Completed?

Once an ethical audit is completed, you'll receive a detailed inspection report the same day. You'll be able to easily access the report through your online QIS account. The report details the audit findings, includes photos of any non-compliance issues, and provides recommendations for corrective actions.

QIS Expertise

QIS provides independent ethical auditing designed to protect your business interests and ensure supply chain compliance. Our neutral industry-standard auditing guarantees that your suppliers meet ethical requirements. Our highly trained and experienced auditors are compliance experts who go through regular training on regulations and best practices. They can be onsite at your supplier's facility within 48 hours of booking. We conduct ethical audits for a diverse range of industries and supply chains across multiple sectors.

QIS Benefits

- In-depth local knowledge with auditors attuned to the culture, laws and practices of their region

- CSR experts receive regular training on regulations and best practice

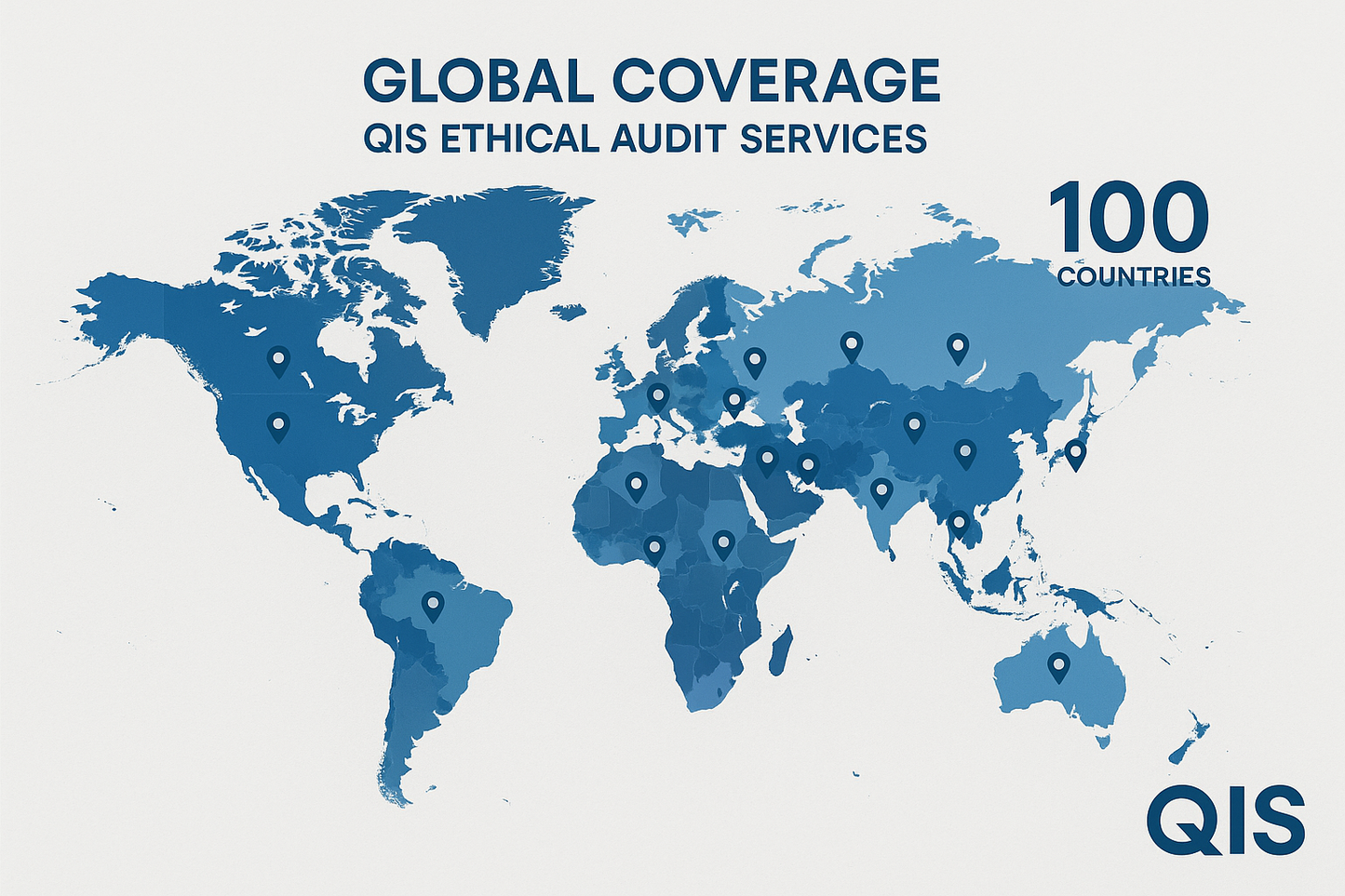

- Global coverage across 100 countries in Asia, Africa, Europe, North and South America

- Continuous improvement approach drives long-term change and empowers suppliers to act

- Online program management book audits, make payments, and download detailed reports

- Custom compliance dashboard to assess supplier performance, track progress and visualize your supply network

- Ranked #1 in the industry for customer satisfaction based on independent NPS measurement

Share