QIS Quality Inspection Services

Production Monitoring (PM) for Production Status Control

Production Monitoring (PM) for Production Status Control

無法載入取貨服務供應情況

Ensure that your manufacturing operations adhere to planned schedules through continuous monitoring

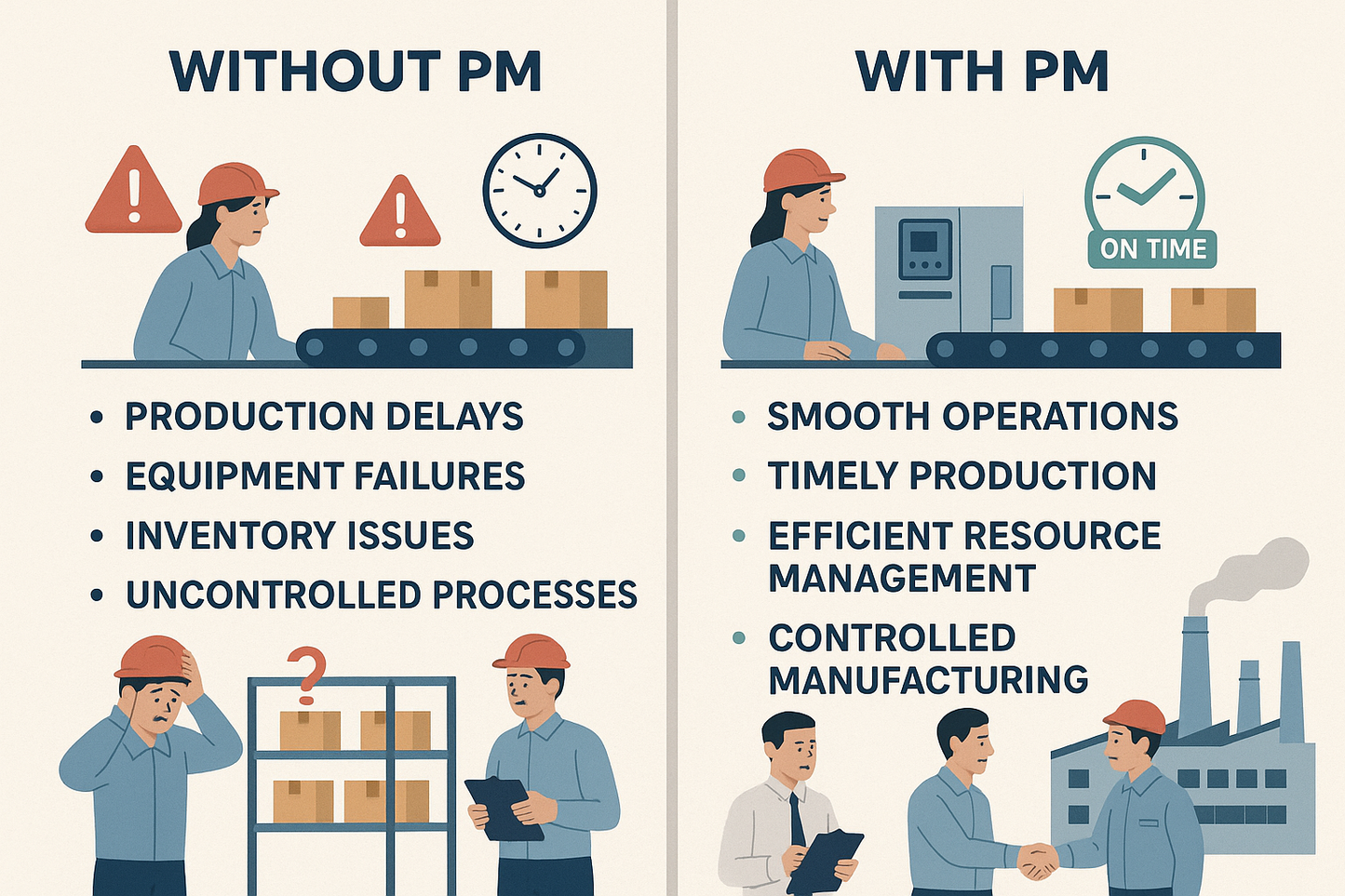

QIS's production monitoring guarantees a more exact production timeline and better quality assurance. This service helps you identify and address delays, equipment failure, warehouse issues, non-compliance, inefficiencies, and other problems that may affect production.

What Is Production Monitoring?

QIS production monitoring is a specialized on-site inspection performed to verify the production status and the inventory of raw materials. Our inspector examines your factory and checks the quantity of the raw materials and accessories required for your products. While conducting production, factory, and manufacturing monitoring, QIS inspectors follow established industry-standard procedures. We provide detailed reporting for the entire or specific production cycle, accessible through our online platform.

Why Do You Need Production Monitoring?

- Keep your factory accountable from start to finish of the production run

- Maintain control and visibility of the entire production process

- Detect the possibility of any sub-contracting

- Prevent production delays

- Identify poor internal quality control from suppliers

- Identify and address issues impacting quality in warehouse or production environments

- Check if the factory's declared production capacity is feasible

A one-time production check offers only a general overview of the overall production status. On the other hand, consistent monitoring over a predetermined period, such as weekly, allows for ongoing tracking and guarantees a more precise timeline and improved quality control.

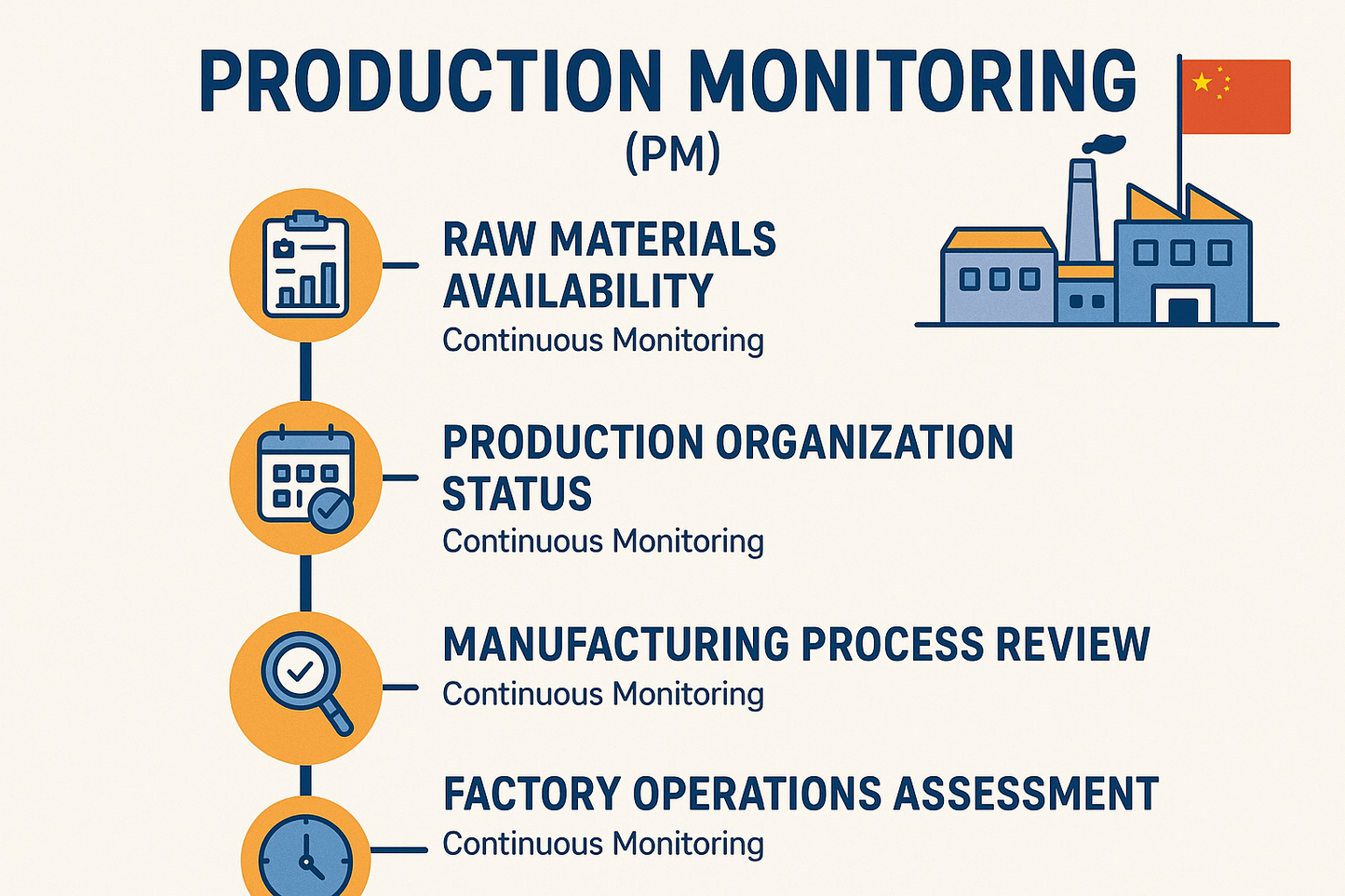

Production Monitoring Process

A typical monitoring process includes the following checks:

- Availability and planning of raw materials and accessories

- Production organization and status check

- Review of the production process and internal factory operations

What are the Next Steps after Completing Production Monitoring?

You receive a detailed inspection report regarding production completion status, accessible through your online QIS account. The report outlines the findings of the inspection, including photos of any deficiencies and an overall pass/fail assessment of the inspection. Production monitoring does not control the quality of your products or corrective action plans for improvement. We recommend pairing production monitoring with a quality inspection during production. This includes using AQL sampling and/or focusing on identifying root causes and implementing corrective actions during production.

QIS Expertise

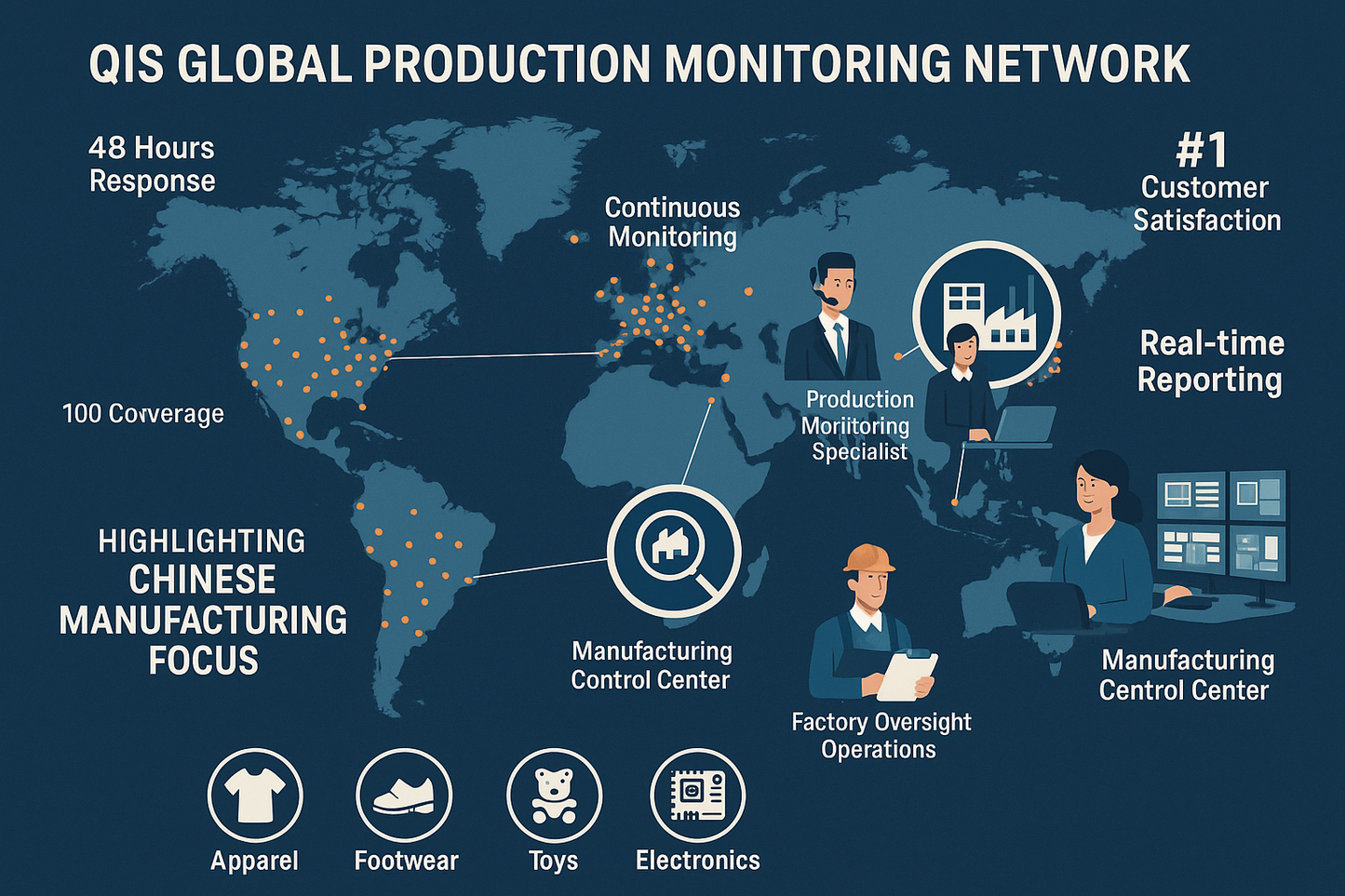

QIS provides independent quality control designed to protect your business interests. Our neutral industry-standard production monitoring guarantees that your production meets your requirements. Our highly trained and experienced inspectors are product experts who go through regular training in their field of specialization. They can be onsite at your factory within 48 hours of booking. We conduct inspections for a diverse range of consumer products, including but not limited to apparel, footwear, toys, electronics, and furniture.

QIS Benefits

- Independent quality control performed by product experts to protect your business interests

- Global coverage across 100 countries in Asia, Africa, Europe, North and South America

- Speed and flexibility with an inspector onsite within 48 hours; modify or cancel up to the day before inspection

- Same-day inspection reports tailored for your product

- Online program management to book inspections, make payments, and download detailed reports

- Custom quality dashboard to identify trends and make informed decisions in real time

- Ranked #1 in the industry for customer satisfaction based on independent NPS measurement

Share